การผสมท่อนมีบทบาทสําคัญในการเชื่อมส่วนประกอบในสาขาต่างๆ โดยเฉพาะในด้านอิเล็กทรอนิกส์และระบบประปา การเลือกชนิดที่เหมาะสม สายบัดกรี เป็นสิ่งสําคัญในการสร้างความยั่งยืน การเชื่อมต่อที่มีคุณภาพสูง วัน นี้ เรา จะ พิจารณา พิจารณา ว่า มี ชนิด สาย เลอ ที่ มี อยู่ ณ ที่ไหน ปัจจัย ที่ ควร พิจารณา เมื่อ เลือก สาย เลอ และ แนวทาง ที่ ดี ที่สุด เพื่อ รับรอง ว่า การ เลอ จะ ประสบ ผล ดี.

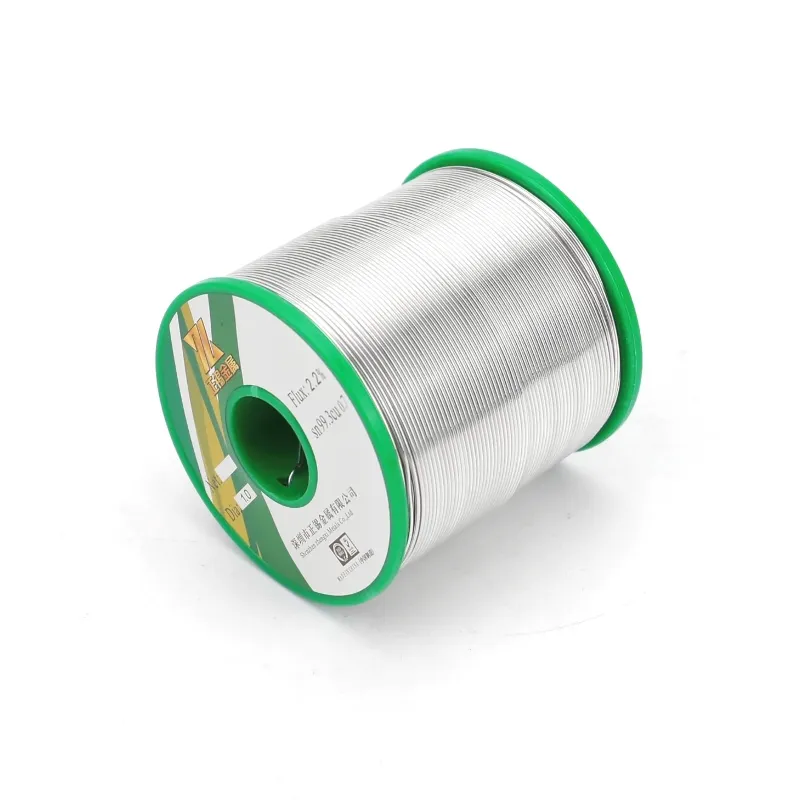

สายผสมเป็นสับสนโลหะสลัก โดยทั่วไปมีหมึกและ鉛 หรือทางเลือกที่ไม่มี鉛 ใช้ในการสร้างความเชื่อมต่อที่แข็งแรงระหว่างองค์ประกอบโลหะ เมื่อร้อนขึ้น สายผสมเหล็กละลายและไหลเข้าสู่ข้อต่อ

สายผสมเป็นส่วนใหญ่ในหลายๆ การใช้งาน เช่น

สายผสมผสมด้วยหมู นําประกอบด้วยผสมของหมึกและหมู นําใช้ในอุปกรณ์อิเล็กทรอนิกส์ เนื่องจากคุณสมบัติการชื้นที่ดีและจุดละลายต่ํา (โดยทั่วไปประมาณ 183-190 ° C) แม้ว่าโลหะเชื่อมด้วย鉛จะให้ผลงานที่ดีกว่า แต่มันได้กลายเป็นไม่ค่อยเป็นที่นิยมเนื่องจากความกังวลด้านสุขภาพและสิ่งแวดล้อมที่เกี่ยวข้องกับการเผชิญหน้ากับ鉛

ด้วยความรู้มากขึ้นเกี่ยวกับปัญหาสิ่งแวดล้อมและสุขภาพ สายลวดที่ไม่มีหมูได้รับการจับยึด โดยเฉพาะอย่างยิ่งในตลาดของสหภาพยุโรปและสหรัฐอเมริกา สายผสมที่ไม่มีหมูประกอบด้วยทองเหลืองส่วนใหญ่ ขณะที่มันมักมีจุดละลายสูงกว่า (ประมาณ 220-260 ° C) มันตอบสนองความต้องการกฎหมายที่เข้มงวดและมักถูกเลือกในแอปพลิเคชั่นที่ทันสมัย

เมื่อเลือกสายผสม ให้แน่ใจว่ามันเข้ากันได้กับวัสดุที่คุณจะทํางาน ตัวอย่างเช่น อิเล็กทรอนิกส์ มักจะต้องการเครื่องเชื่อมที่ออกแบบมาเพื่อทองแดง โดยเฉพาะ การใช้งานด้านระบบประปา ต้องการผสมผสมที่เหมาะสมสําหรับเชื่อมต่อท่อโลหะ

กว้างของสายผสมผสมส่งผลต่อการถ่ายทอดความร้อนและขนาดของข้อผสมผสม สายใยบาง (มักจะอยู่รอบ 0.5 มม.) ใช้ในการทํางานที่ละเอียด بينماสายใยหนากว่า (1.0 มม.ขึ้นไป) เหมาะสําหรับการเชื่อมต่อขนาดใหญ่ การเลือกเส้นผ่าตัดที่เหมาะสม เป็นสิ่งสําคัญในการสร้างสรรค์สานผ่าที่แข็งแรงและน่าเชื่อถือ

น้ํามันไหลเป็นสิ่งสําคัญสําหรับการผสมผสานที่มีประสิทธิภาพ เพราะมันทําความสะอาดพื้นผิวที่จะผสมผสานและปรับปรุงการไหลของผสมผสาน สายผสมสามารถมีประเภทของไฟล์สที่แตกต่างกันได้ เช่น

เพื่อสร้างสรรค์สับผ่าที่แข็งแรงและน่าเชื่อถือ ใช้เทคนิคดังนี้

สักครั้งต้องรักษาความปลอดภัยระหว่างการผสม เพื่อป้องกันตัวเองจากอันตราย:

การ เข้าใจ ประเภท และ การ เลือก สาย เลอ ด์ จะ ช่วย ให้ โครงการ เลอ ด์ ของ คุณ ดี ขึ้น ไม่ ว่า จะ เป็น ใน สาขา อิเล็กทรอนิกส์, ปลูก ไม้ หรือ ใน สาขาอื่น ๆ. โดยพิจารณาความเข้ากันของวัสดุ กว้างของสาย และประเภทของกระแสไฟ คุณสามารถทําให้เชื่อมต่อที่มีคุณภาพที่ทนการทดสอบของเวลาได้ การ ทํา งาน ที่ ดี สวัสดีด้วยการผสม

Copyright © 2024 Shenzhen Zhengxi metal Co.,LTD